S83 ROCK DRILLS

THE MOST POWERFUL DRILL ON THE MARKET

BTE Mid-Western has been manufacturing quality rock drills and replacement parts since the 1940’s. We are the only true OEM of the S83 line of Jackleg, Stoper, and Sinker drills as well as the TUL2B and FL7 Feed Legs. We acquired all the intellectual technology from Gardner Denver in the 1980’s and we have been manufacturing the S83 drill line under the BTE Mid-Western name ever since. We have been the leader in the mining and construction industries for decades. Our powerful drills hit harder and penetrate rock faster than any other drill on the market. Many companies have copied our S83 name but if you want the best you need to buy a true BTE Mid-Western drill. Our products might cost a little more than the foreign competition but the quality cannot be surpassed.

LOOKING FOR PARTS?

What kind of S83 rock drill do you have?

The most dependable jackleg drill on the market! This workhorse has been the industry leader for decades, and for good reason. It’s hard-hitting and has fast penetration rates with low maintenance costs. Careful weight distribution and balance provide greater operator efficiency with less fatigue. Available with either standard telescopic feed legs or power retractable feed legs in a number of lengths for plenty of versatility.

The power of the S83 jackleg in a sinking hammer. Great for shaft sinking, quarry work, construction work, and utility work. It comes equipped with heavy-duty neoprene rubber grips for added comfort.

A powerful and robust stoper drill that’s great for overhead applications. This unit has plenty of power and torque to drive roof bolts and fasten roof bolt nuts. Available with two leg options for better access in tight spaces.

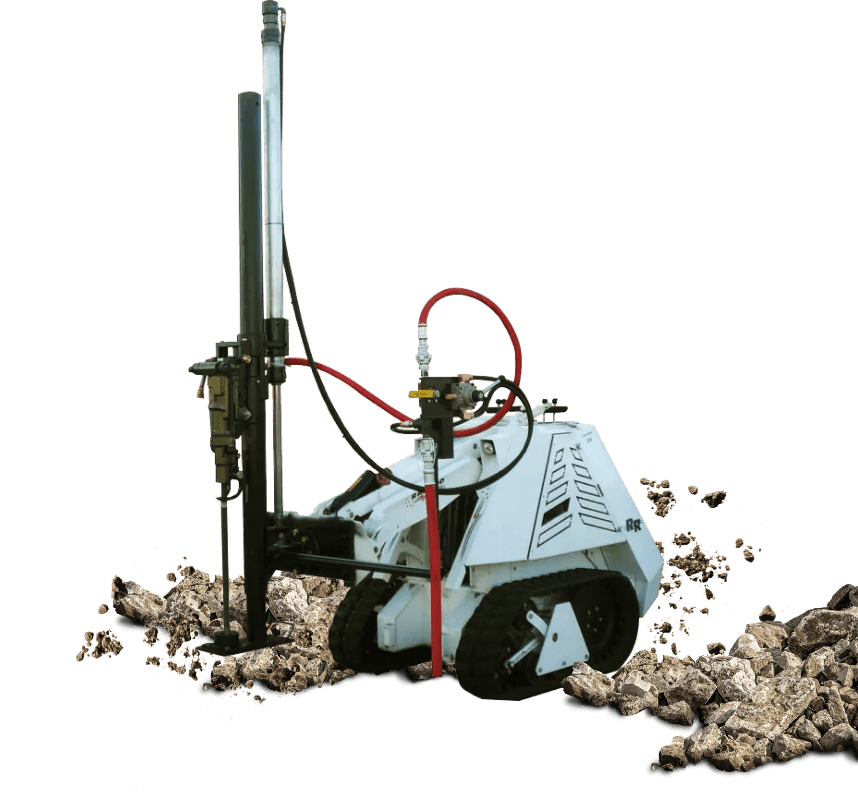

Have a project that needs multiple holes drilled? Our Demon Drill may be the solution for you. Our line of S83 hand-held drills have been used in mining and construction projects across the world for decades.

We have harnessed the power of the S83 drill and mounted the unit to a feed system so you no longer have to physically hold the drill. The result is a hard-hitting, powerful, efficient, rock drill with no operator fatigue. With so many applications, The Demon Drill is a great fit for surface and underground mines, quarries, geotechnical drilling companies, jacking and grouting companies, construction companies, utility companies, road crews, fencing contractors, and more.

-

COMPLETELY PNEUMATIC OPERATION (STROKE, ROTATION, AND HAMMERING)

-

SIMPLE, EASY-TO-USE CONTROLS

-

UNIT CAN TILT AND LOCK IN PLACE UP TO 30 DEGREES TO THE LEFT AND RIGHT

-

AVAILABLE WITH A 2” RECEIVER HITCH MOUNT OR A PLATE MOUNT TO ATTACH TO EQUIPMENT

-

HOLE DIAMETERS RANGING FROM 5/8” TO 3”+ 2,302 BEATS PER MINUTE (WHEN DRILLING AT 90 PSI

-

2,302 BEATS PER MINUTE (WHEN DRILLING AT 90 PSI)

SPECIFICATIONS

| US | Metric | |

|---|---|---|

| Piston Diameter | 3" | 76 mm |

| Length of Stroke | 2.5" | 64 mm |

| Overall Length | 27-1/4" | 688 mm |

| Total Weight | 72 lbs. | 32.4 kg |

| Air Hose Size | 1" | 25 mm |

| Water Hose Size | 1/2" | 13 mm |

| Chuck Size | 7/8" or 1" x 4 1/4" | 22 mm or 25 mm x 108 mm |

|

Pressure (PSI) |

Percussion Speed (Impacts per Minute) |

Energy Per Blow (LB/FT) |

|---|---|---|

| 80 | 2,256 | 59.6 |

| 90 | 2,302 | 69.2 |

| 100 | 2,418 | 84.8 |

ROCK DRILL OPTIONS

| Item Number | Drill Type | Steel Size | Leg Model |

|---|---|---|---|

| MWS83FA | Feed Leg Drill | 7/8" (22 mm) | FL7 |

| MWS83FB | Feed Leg Drill | 1" (25 mm) | FL7 |

| MWS83FC | Feed Leg Drill | 7/8" (22 mm) | TUL2B |

| MWS83FD | Feed Leg Drill | 1" (25 mm) | TUL2B |

| MWS83DA | Sinker Drill (Dry) | 7/8" (22 mm) | N/A |

| MWS83DB | Sinker Drill (Dry) | 1" (25 mm) | N/A |

| MWS83WA | Sinker Drill (Wet) | 7/8" (22 mm) | N/A |

| MWS83WB | Sinker Drill (Wet) | 1" (25 mm) | N/A |

| MWRB83A | Stoper Drill | 7/8" (22 mm) | RB83TUL |

| MWRB83B | Stoper Drill | 1" (25 mm) | RB83TUL |

ADDITIONAL EQUIPMENT

| Item Number | Description |

|---|---|

| FL990X | Swivel assembly to connect Jackleg drills with TUL2B style legs |

| 1FL7310X | Swivel assembly to connect Jackleg drills with FL7 style legs |

| MWS83FM | Wrap-around muffler assembly for S83 rock drills |

| MWLO7B | Air line lubricator with 1.5 pint capacity |

ROCK DRILL OIL

| Item Number | Temperatures | ISO Viscosity Grade | Minimum Flash Point |

|---|---|---|---|

| MRD127-ISO32 | Below 20F (-7C) | 32 | 360F (182C) |

| MRD127-ISO68 | 20F to 40F (-7C to 4C) | 68 | 405F (207C) |

| MRD127-ISO100 | 40F to 80F (4C to 27C) | 100 | 420F (216C) |

| MRD127-ISO150 | 80F to 110F (27C to 43C) | 150 | 445F (229C) |

| MRD127-ISO220 | Above 110F (43C) | 220 | 470F (243C) |

REQUEST A QUOTE

We pride ourselves in delivering our customers the best supplier relationship possible. We know you have a lot of choices where you buy your products, and we appreciate the opportunity to work with you.